Mia Elg, R&D Supervisor at Deltamarin, says there’s not lots of the firm’s new designs, it doesn’t matter what the vessel sort is, that don’t embrace batteries.

Putting in smaller battery capability to a diesel engine pushed vessel with electrical energy practice can allow spinning reserve. Right here, an optimum variety of engines will be stored on-line, and the batteries can work as a black out preventer. This will save, relying on the kind of the ship and operation, something between just a few p.c to tens of p.c if the ship is in any other case required to maintain an enormous reserve of engines on-line.

Along with spinning reserve, the batteries can carry out peak shaving operate, to additional make sure that the engines are stored on mounted load near the gasoline effectivity optimum level. For these two capabilities, the battery capability doesn’t must be massive. It’s primarily for varied zero emission operation modes and even overlaying the primary voyage time, when bigger capacities are required.

Having batteries for spinning reserve or peak shaving for a cargo’s ship auxiliary equipment powertrain may also equally optimize the genset effectivity. Cargo ships usually have massive thrusters or cranes that take massive portions of energy for a short while. On this case, battery capability might change the necessity of 1 auxiliary genset.

The gasoline financial savings in battery-hybrid or battery pushed ships are strongly associated to the gasoline, equipment configuration, and operational profile of the ship, says Elg. “We’ve got lately studied, as an example, for an LNG-fueled RoPAX ship sort with two sorts of battery units for varied routes: a smaller however nonetheless multi-MWh sized battery pack, primarily used for spinning reserve and peak shaving, and a completely electrical RoPAX.

“Within the smaller battery pack case, the financial savings are very a lot relying on the route. We checked out a route within the Mediterranean with somewhat lengthy distance and stuck pace at sea with little or no maneuvering, the route throughout English Channel and a route at Baltic Sea, together with a lot maneuvering within the archipelago at variating pace.

“Because the chosen final analysis equipment was very environment friendly, the gasoline financial savings have been average, from 0.5% to lower than 5% in all instances. However with completely different fuels and, as an example, older machineries the financial savings could also be bigger. Due to this fact, battery retrofits with smaller capacities are additionally attention-grabbing in the mean time for a lot of ship house owners.”

Deltamarin additionally analyzed the potential of batteries for a completely battery powered RoPAX working on the English Channel route. “The design can be extra possible to attain, and I consider it’s not a lot gasoline saving we should always concentrate on however the operational complete prices.”

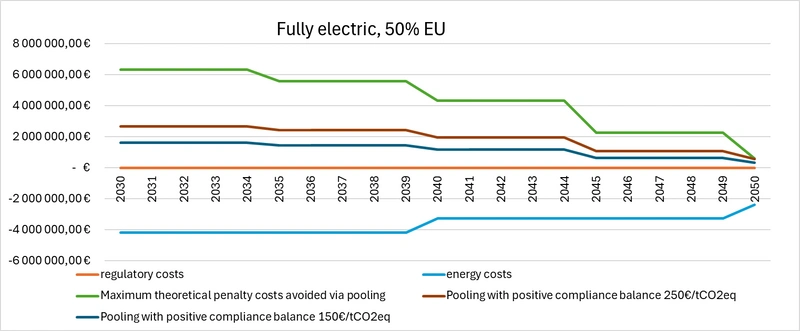

Relying on precise electrical energy costs over the subsequent few a long time, the general pure power prices for the vessel can be lower than for LNG.

Moreover, relying on the worth placed on carbon, it is perhaps doable to pool the vessel and get some further earnings. This might attain a number of million euros per yr and would cowl a lot of the set up prices for the batter system.

“That is to me a key characteristic why in some instances batteries make extra sense earlier than various fuels at the least right here in Europe,” says Elg.

Ought to the batteries be mixed to various fuels or renewables?

“We should at all times perceive the vessel massive image for answering this. On the whole, you might say that having power saving and renewable energy like wind or solar, decreasing the facility utilization onboard is at all times constructive. Batteries might additionally even out the peaks on account of renewables not being there on a regular basis.”

Ships with gasoline cells and hydrogen as gasoline, as an example, will doubtless want batteries, however when involves different fuels, it’s good to discover a steadiness between CAPEX and the variety of applied sciences used onboard. “For example, for an ocean-going cargo vessel, batteries is not going to anyway be an answer to energy them 100%. In these instances, it could possibly be smart to organize the primary propulsion equipment for various fuels equivalent to methanol or ammonia, and batteries could possibly be utilized to spice up the auxiliary energy practice.”

It’s commonplace at the moment to incorporate a PTO/PTI configuration on many cargo vessels, says Elg. Which means at sea, usually, the auxiliary engines should not utilized in regular operation. Relying on the put in battery capability, they might do extra than simply function spinning reserve. Mixed with shore energy, they could possibly be used for zero emission harbor arrival and departure.

“Whether it is doable to attach the batteries to shore aspect charging, electrical energy could possibly be seen as one of many various fuels,” she says.

Nonetheless, introducing new gear inevitably introduces added weight to the ship and added funding. Ship electrification may also not be doable in all places with out appreciable funding in infrastructure, so all tasks are very case-dependent.

“I’ve seen that at the moment there exists corporations which have as enterprise to supply power storage options together with the batteries and charging infrastructure, additionally for harbors. Due to this fact, the ship proprietor or port operator really doesn’t must essentially make investments a lot CAPEX within the electrical infrastructure, however they could pay a month-to-month price or premium on prime of the electrical energy value for the service. It simply makes this electrification much more attention-grabbing and possible to ship operators.”

In some instances, it is perhaps smart to organize the ship for a wide range of energy-saving applied sciences or electrical energy storage, however to put in a number of the capability later when the economical calculations assist it.

“It’s a balancing train, and because of this we now have launched digital design and power system modelling processes in our designs, each for newbuilding and retrofit tasks.”

Source link