Timo Vesala, Account Supervisor, Americas, at ABB Marine & Ports, is chargeable for newbuild gross sales within the Americas market. Since becoming a member of ABB in 2018, he has gathered intensive expertise within the marine trade with a deal with electrification and propulsion programs. He holds a Grasp’s Diploma in Mechanical Engineering from Aalto College, Finland, and has a ardour for clear know-how and maritime decarbonization. This month, in our annual Energy & Propulsion version, he weighs in the way in which ahead to a greener world waterfront.

All American Marine and ABB not too long ago collaborated on new hybrid-electric ocean sampling vessel in California. Inform us about that undertaking and the way it took place.

We’re excited to collaborate with All American Marine on this revolutionary undertaking for Orange County Sanitation for his or her new ocean sampling vessels. This 19.8-meter vessel has been designed by Auckland based mostly naval architect Teknicraft to assist Orange County Sanitation District’s ocean monitoring program that has run for over 40 years in assist of wastewater assortment, therapy, disposal, and recycling providers for two.6 million residents of Orange County, CA. This system operates round 90 days annually, verifies that the Pacific Ocean stays protected for swimming, marine life and fisheries.

The undertaking was closely pushed to satisfy the California Air Assets Board’s requirement for 30% of propulsion to be offered by zero-emission sources. Within the final couple of years, ABB has been growing options for smaller vessel purposes, bringing options to the market that had been initially developed for heavy responsibility landside utility comparable to mining and off-highway e-mobility. The primary instance of such options was for 2 vessels for Maid of the Mist, which had been among the first all-electric passenger vessels within the US.

Our collaboration with All American Marine has been extraordinarily fruitful to date and we have now been studying rather a lot ourselves, particularly with regards to the load and area sensitivity on smaller catamaran vessels.

ABB’s hybrid-electric propulsion system will allow the ocean sampling vessel to satisfy the California Air Assets Board’s annual equivalence necessities for Zero-Emission Succesful Hybrid Vessels. Would a Tier 4 EGR or SCR resolution be as clear? Why or why not?

There isn’t any easy reply to this query, because it actually will depend on the operational profile of the vessel and what you imply by hybrid-electric propulsion system. Each EGR and SCR are applied sciences designed to scale back emissions from engines, however they nonetheless depend on the combustion of fossil fuels. Though they considerably can cut back dangerous pollution, together with NOx and different issues, they don’t get rid of the emissions fully. Within the hybrid-electric propulsion system we’re delivering for Orange County Sanitation District along with All American Marine, we’re permitting the vessel to run on electrical energy for sure operations, particularly round port and through sampling operations. This reduces the necessity for gasoline combustion, resulting in zero or near-zero emissions when working on electrical energy. Relying on the supply of the electrical energy, the system can have a much smaller carbon footprint, particularly if paired with renewable vitality sources. The vessel can also be designed to be future proofed for brand spanking new applied sciences; working extra on electrical energy by growing the battery capability and lowering the operations on engines.

“Within the hybrid-electric propulsion system we’re delivering for Orange County Sanitation District along with All American Marine, we’re permitting the vessel to run on electrical energy for sure operations, particularly round port and through sampling operations. This reduces the necessity for gasoline combustion, resulting in zero or near-zero emissions when working on electrical energy.”Timo Vesala, Account Supervisor, Americas, at ABB Marine & Ports

The brand new ocean sampling catamaran for the Orange County Sanitation District is about 19 meters lengthy. That mentioned; what’s the candy spot in your know-how, when it comes to vessel dimension, tonnage and repair?

ABB is uniquely positioned out there with options that vary from a 65 -foot aluminum catamaran to bigger ferries and cruise ships. Historically, ABB’s options have been centered on giant medium voltage AC or DC purposes, such of ice-going vessels, mid/giant dimension ferries and the cruise market. Nevertheless, the answer we have now developed for the Orange County Sanitation District vessel can vary from simply 200 kW as much as 2 MW.

The vessel will likely be constructed to satisfy California Air Assets Board’s annual equivalence necessities for Zero-Emission Succesful Hybrid Vessels, which mandate that at the least 30 p.c of complete annual energy should come from zero-emission energy sources. That’s a excessive bar to clear. Are you seeing these sorts of laws in some other markets?

I’d count on that different states will look to comply with California’s lead sooner or later. Many within the trade have their eyes on the CARB laws to see how industrial operators will comply and what applied sciences will come up to assist ease the transition. As know-how continues to enhance and adoption of low and nil emitting options will increase, it can allow different areas to enact comparable necessities to enhance total air high quality.

The brand new catchphrase for clear and inexperienced propulsion is hybrid electrical. 5 years in the past, it was diesel electrical. Is there a distinction, and in that case, clarify how and why.

In a diesel-electric propulsion system, the vessel makes use of a diesel engine to generate electrical energy, which is then used to energy motors that drive the vessel’s propellers. Because of this the engines are the first supply of energy for producing electrical energy, and the electrical motors permit for extra environment friendly operation and smoother management than a mechanical drive system. A hybrid-electric propulsion system provides a brand new layer of flexibility, combining each diesel engines and one other vitality supply (batteries, gasoline cells, and many others.). Sometimes, in a hybrid-electric propulsion system, engines are the first supply of energy for top energy and long-range operations. Vitality sources comparable to batteries are used for low-speed, short-range operations or when the vessel is working round ports or for instance environmentally delicate areas.

The arrival of the ‘diesel electrical’ offshore service vessels (OSV) grew to become commonplace through the offshore increase period. These offshore programs had been, by and enormous, too large to suit into a traditional inland pushboat. Discuss in regards to the effort to scale these applied sciences down for the inland, coastal, and harbor operators.

Working with All American Marine on the Orange County Sanitation District vessel has pushed us to discover a resolution on a vessel that’s extraordinarily weight and space-sensitive. Numerous the know-how used was initially developed for heavy responsibility landside utility comparable to mining. Because the know-how additional develops, we will hopefully push much more efficiency from this tools to handle excessive energy operations workboats generally face.

Has the progress with the battery market – smaller, lighter packages becoming extra storage capabilities, for instance – made it simpler to suit these hybrid programs on board smaller platforms? What’s anticipated within the close to future on this difficult area?

Battery programs are per definition modular buildings, constructed up from cells forming sequence strings to full vitality storage programs. As such, batteries have been put in in small vessels comparable to river boats and sightseeing vessels already within the early days of marine electrification. The current developments within the battery know-how have nonetheless allowed for increased vitality density and extra compact designs. One other vital side is the lowering price ranges for batteries generally. This helps to make hybrid and full electrical propulsion commercially viable for an growing variety of vessel segments and use instances.

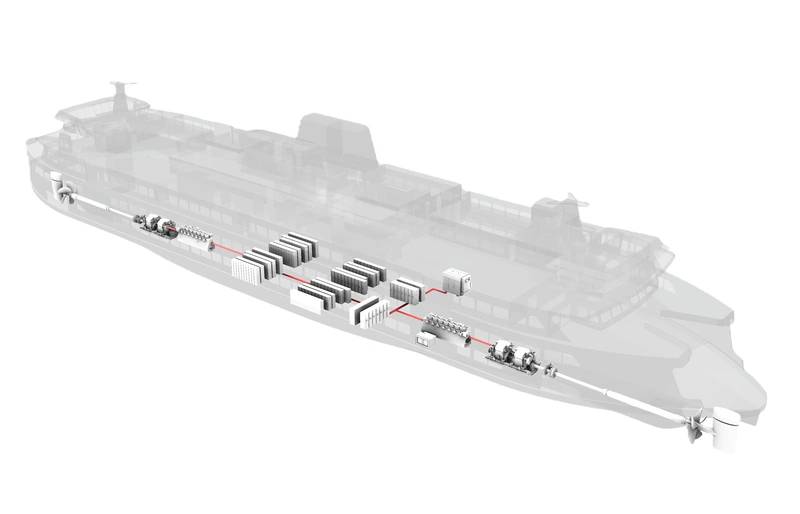

A illustration of ABB’s grid to propeller system. Picture courtesy ABB

A illustration of ABB’s grid to propeller system. Picture courtesy ABB

The ‘standard’ propulsion possibility entails putting in two giant EPA Tier 4 foremost engines supplemented by an aftertreatment system – both the Exhaust Gasoline Recirculation (EGR) or Selective Catalyst Discount (SCR) possibility. The latter selection can add extra piping, a refill and urea storage tank and demand separate upkeep all inside the confines of an already cramped equipment area. Is the ABB engine hybrid electrical resolution conducive to a extra roomier engine area – and, for that matter, liberating up area for different vessels’ wants?

In a traditional propulsion system, assembly stringent emission requirements usually requires to be supplemented with extra parts comparable to EGR or SCR. ABB’s hybrid-electric propulsion system usually permits the vessel to function with smaller engines, as a result of means to run on electrical propulsion in sure circumstances. This reduces the scale of the engine required and should even permit for downsizing the engine room total. Moreover, having an electrical propulsion system provides you vital flexibility, as lots of tools will be freely positioned in unused or area elsewhere on the vessel, additional liberating up area within the engine room. The ocean sampling vessel for Orange County Sanitation District is extraordinarily weight and area delicate, subsequently being the primary design driver in our resolution and tools chosen.

Discuss in regards to the prospect for future towboats, inland pushboats and myriad workboats being routinely all-electric. Will that be attainable, when will it occur, and what’s going to it take to get there?

The trade is laying the groundwork for electrification, and as battery know-how advances and demand for sustainable operations grows, the widespread us of all-electric workboats turn out to be more and more possible. We already see vessels working in harbors or port services being the primary adopters of all-electric programs. Nevertheless, there may be nonetheless work that must be carried out on the technological development, regulatory frameworks, infrastructure, and the economics. The following decade will seemingly see hybrid programs as the commonest resolution, with all-electric vessels changing into extra routine as battery applied sciences enhance and infrastructure for charging expands. Authorities laws and incentives, comparable to grant funds and emission laws, will play a essential function in accelerating the adoption of totally electrical vessels.

It isn’t simple to make apples-to-apples comparisons for gasoline consumption, economic system, NOx, SOx and particulate matter numbers between standard engine preparations and a hybrid electrical resolution. Nonetheless, give us a basic concept of what the everyday workboat operator MIGHT count on.

It’s certainly fairly difficult to make a direct apples-to-apples comparability as a result of variability in operational circumstances and profile. Workboats are a horny vessel sort from a hybridization point-of-view for the next causes:

Mixture of excessive and decrease demand operationsShort operational cycles, frequent port calls.

In a hybrid system, gasoline effectivity can enhance considerably, because the hybrid system permits the engine to function at its optimum load (increased effectivity), lowering gasoline consumption in comparison with standard programs that always run at suboptimal ranges. A hybrid system additionally gives decrease put on and tear, because the engine isn’t consistently working at full load, resulting in much less frequent upkeep and doubtlessly longer intervals between overhauls. Usually, a hybrid resolution for workboats gives advantages when it comes to gasoline consumption, emission reductions, and total operational effectivity. Operators can count on vital financial savings over time, each when it comes to gasoline prices and upkeep.

Is the ABB hybrid electrical resolution, for probably the most half, OEM agnostic?

Sure, as an electrical system integrator, ABB’s hybrid-electric resolution is for probably the most half OEM agnostic. We at all times attempt to promote our personal tools the place it is sensible, however in lots of instances, we choose OEM’s based mostly on the client’s operational wants and preferences. Our resolution is modular and versatile, which permits us to decide on one of the best resolution and tools for various vessel sorts and operations, whatever the producer. As well as, we have now developed sturdy partnerships with a variety of companions and OEM’s (engines, vitality storage options, energy distribution, and many others.), which permits us to be appropriate with numerous varieties of tools and supply prospects with choices based mostly on their operational wants. Leveraging our inhouse experience with system integration, ABB has intensive expertise out there, which means we will work with numerous OEM parts and make sure the resolution can work seamlessly with completely different producers’ tools.

Give us an concept of price differentials between the hybrid electrical resolution and traditional engine preparations.

We are able to say that normally hybrid options are dearer up entrance, however pay for themselves over time in that they’ve decrease OPEX and improved effectivity

By the 12 months 2020, ABB had already equipped over 1,300 vessels that includes diesel electrical propulsion. Share, if you happen to can, the most recent numbers for ABB’s penetration into the workboat markets.

So far, ABB has electrified over 1500 vessels and digitally linked over 2000 vessels and ports worldwide.

On an ABB engineered hybrid resolution, do you act because the integrator, successfully offering a single level of contact for upkeep and repair points?

Sure, as {an electrical} system integrator, ABB takes the duty of integrating all the assorted parts of the hybrid propulsion system and warrants all tools inside our scope, subsequently performing as a single level of contact with regards to sustaining and servicing the tools. This method streamlines operations for vessel operators and ensures that each one tools in our system work seamlessly collectively.

For the everyday harbor tugboat, these vessels all have what trade stakeholders have dubbed, “the hour of energy.” In different phrases, that time period when most energy should be accessible for such heavy-duty duties comparable to pushing alongside a VLCC or towing a string of barges. In a hybrid electrical configuration, or a pure electrical mode, will that “hour of energy” even have the ability to rely on the hybrid resolution?The “hour of energy” can certainly be dealt with in hybrid electrical or totally electrical system; how it’s achieved will depend on the design and capability of the system. Sometimes, with a hybrid system, that is achieved with a mixture of engines and batteries; consider the battery utilization as an instantaneous energy increase. The batteries are designed to complement the engines throughout this high-power state of affairs. In a well-designed system, the engine at all times operates at its optimum effectivity, even throughout these high-power operations. For a totally electrical system, it’s all about the way you dimension your batteries to satisfy the ability wants of your operations. A totally electrical workboat usually requires giant battery capability to ship excessive energy for prolonged intervals. Having good knowledge of the present operations is significant to know the vary and working time of the vessel. As battery know-how advances, extra workboat operators who beforehand couldn’t take into account totally electrical programs as a consequence of issues about vary or energy output will discover themselves with viable choices.

Inland towboats and barges signify 85 p.c of U.S. vessels and towboats are the oldest with as many as two-thirds of that sort of vessel older than 25 years. The technique of rising a fleet by acquisition of present property is not going to be viable into the foreseeable future. Or, will it? Can present property be retrofit for hybrid options?

We strongly consider progress must be achieved by a mixture of new builds and retrofitting present property. Hybrid programs are modular, which means present towboats can profit from the know-how at present accessible to enhance gasoline effectivity, cut back emissions and adjust to regulatory requirements. Retrofitting present towboats is a viable and sustainable resolution, though it will probably current challenges. Older vessels might need restricted area and structural capability for integrating trendy hybrid applied sciences and would possibly require vital modifications to the hull or equipment areas. As well as, including electrical motors, batteries, and different hybrid tools can considerably impression the load distribution and stability of older vessels. Cautious planning and a robust partnership with stakeholders are each important to make sure that the vessel stays seaworthy.

Source link