What Is Fresh Water Generator ?

A Fresh water generator is used on ship for production of fresh water from ocean water for domestic and auxiliary functions , which is a vital demand aboard ships.

A considerable quantity of H2O is consumed on a ship. The crew consumes an average 100 liter/head/day. onboard a steam ship the boiler consumption may be as high as thirty tons per day, as more water will need to be produced for the large steam demand. The average freshwater consumption on these ships can vary anywhere between 500-1000 tonnes per day.

On cruise ships, fresh water is required for drinking, galleys, laundries, high-pressure washing & cleaning purposes, steam generation (distilled water), various heating & cooling systems within and outside the machinery spaces, sprinkler and hyper-mist systems for fire-fighting and recreational purposes (swimming pools & water-slides).

With this much consumption, it is imperative that cruise ships be equipped with freshwater production and storage facilities that match these requirements.

How Pure Water Produced On Ship ?

Pure water produced on ship ships generally using two Methods ;

- Distillation

- Reverse Osmosis.

Reverse osmosis is normally used in passenger ships where large quantities of water is consumed such as cruise ships.

A typical RO plant onboard is a compact unit with a much smaller footprint than a flash evaporator. It has a capacity of 12-15 m3/hr depending upon seawater quality and the condition of the filters.

A cruise ship can have one or two RO plants, depending upon the requirement.

Distillation Systems

Fresh water from sea on ship is produced mainly by Distillation process.

What Is Distillation ?

- Distillation is the method of production of pure water from sea water by evaporating and re condensing .

Distilled water is made as a results of evaporating ocean water either by a boiling or a flash process.

This evaporation enables the reduction of the 3200 parts per million of dissolved solids in sea water down-to the one or two percent in distilled water.

Boiling Process

This type of evaporator boils sea water at a saturation temperature corresponding to the evaporator pressure and is known as a boiling evaporator.

In a boiling Evaporator, water is maintained continuously at its saturation temperature-in other words, Latent heat is added.

While in the flash evaporator, sensible heat is supplied.

- Submerged tube type- Boiling Evaporator or tube type

- Boiling Process Evaporator ( low pressure evaporator ) Alfa laval or plate type :-

Flash Process (Flash Evaporator )

- This type of evaporator heats the water in one compartment before it is released into a second compartment in which the pressure is substantially lower, causing some of the water to flash into vapour .

- This type of evaporator is known as flash evaporator .

- In flash evaporator, sensible heat is supplied.

Types /Classification

On the basis of of Working Principle ,it is classified into

- Distillate Type

- Reverse Osmosis

- Distillation is cheaper and efficient for less quantity, but RO is expensive and used for production in a large quantity.

- RO is used on a passenger ship, where a large amount of water is consumed.

- Distillation = (Evaporation + Condensation)

- Reverse Osmosis = (Semi permeable membrane filter)

Distillate type is again classified based on the evaporator and condenser structure, i.e

- Plate type and

- Tube type fresh water generator

- Tube type ,also known as the submerged type, because the steam coils are submerged.

- Sometimes it is known as Boiling FWG.

Main or Various type of fresh water generator which are mainly used on ships are :

Submerged Tube Type

- Plate Type

- Reverse Osmosis Plant

The Main components Of A Fresh Water Generator

- Heat Exchanger

- Distillate pump

- ejector pump

- air brine eductor

- Salinometer

- demisters or mesh separator

1.Heat Exchanger

- Evaporator :- It is used to boil off the sea water at lower temperature with the help of vacuum created inside the fresh water generator shell.

- Condenser: It use s the sea water to cool down; and condense the steam to achieve distilled water

2.Fresh Water Pump / Distillate Pump

- It is used to supply the generated fresh water to ship’s fresh water tank by taking the suction from fresh water generator.

Normal rated capacity -3m^3/hr

3.Ejector Pump

- It is used to supply pressurised water to the eductor for creating vacuum.It also supplies cooling water to condenser(to cool the fresh water vapours)

Rated capacity–20-30m^3/hr

Pressure- 3-6 bar

4.Air Brine Eductor:

- It is used to to remove accumulated brine and salts deposits from the generator and create necessary vacuum.

5.Salinometer:

- It is connected to the distillate output just before the solenoid operated three way valve. It is used for measuring the ppm of fresh water produced which is generally (1-2ppm)

The salinometer works on the simple principle that pure water does not conduct electricity; and its conductivity increases with increased dissolved impurities and salts.

What Is Demisters In Fresh Water Generator ?

6. Demisters:

- This is used to separate sea water droplet from the steam vapour.

- A demisters is a thickened layer of mesh structure; fitted in between the evaporator and the condenser element.

- A demisters can be made of nickel, monel metals, copper, stainless steel and synthetic fibers; such as Polypropylene and PVC.

- Typically; demisters made of monel metal are used for the generation of fresh water.

- when the water evaporates it carry over some fine little molecules of water along with the rising steam.

- When the source of such water is sea; it can considerably increase the salinity of output water.

So to maintain salinity as low as 5 to 15 ppm; we use demisters which restrict the passage of mist and pass dry steam.

How Fresh Water Generator Works ?

Working Principle

- The basic principle of all low-pressure freshwater generators is that the boiling point of the water can be reduced by reducing the pressure of the surrounding atmosphere.

- Water can be boiled at low temperatures by maintaining a low pressure, say 50 degrees Celsius.The heat source for the freshwater generator could be waste heat rejected by main engine jacket cooling water.

- Hence,boiling can take place at about 40 to 60 degrees Celsius by using energy from a heating coil and by reducing pressure in the evaporator shell.

- This type of single-effect plant is designed to provide a better economy than obsolete boiling evaporators.

Plate Type Fresh Water Generator

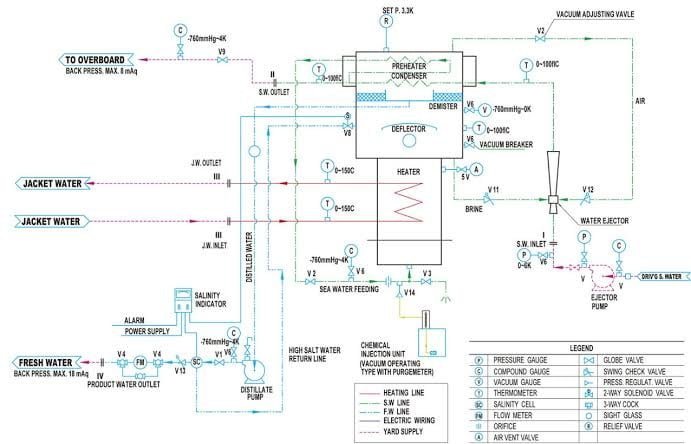

- If the condenser and evaporator Heat exchangers of a fresh water generator is composed of plates then that type of freshwater generator is called Plate type freshwater generator.

- The main components are condenser and evaporator heat exchangers, brine air ejectors, seawater pumps, distillate pumps, salinometer, demister, water flow meters, etc.

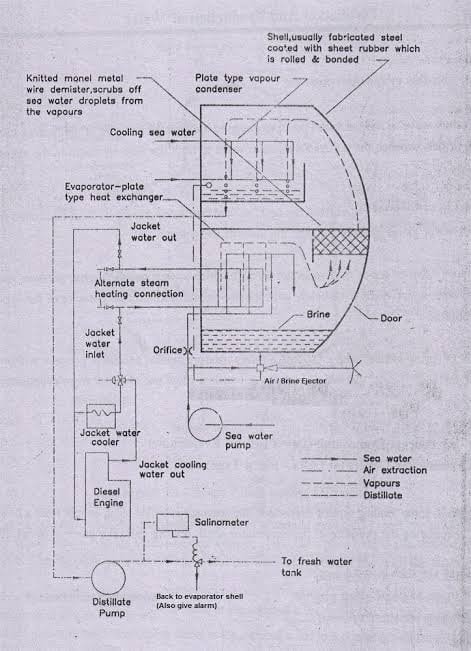

Below You can see the line diagram.

- Fresh water generator uses heat from main engine jacket cooling system which often cooling the engine passes through evaporator to evaporate the sea water feed into it.

- But the jacket cooling water temperatures available is about 70-80 degree celcius,whereas boiling of water is 100 degree Celsius at 1 atm.

- so in order to evaporate sea water at 70 degree Celsius we need to reduce pressure.

- This is done by creating vacuum inside chamber si that sea water get evaporated below 100 degree celcius and also vacuum helps to evaporate easily.

- This vaccum is created by air or brine ejector.

- Now,the evaporated sea water passes through demisters which scrubs off sea water droplets from water vapour.

- Unevaporated water/ particles is discharged as brine (by means of a combined air / brine ejector).

- This vapour passes through the condenser which condense the vapour and get collected at the bottom which is transferred to fresh water tank ,where it is passed through salinometer and controlled by three way solenoid valve.

- The feed rate to the evaporator is fixed at the feed inlet to the evaporator by the orifice plate throughout the entire process.

- If the salt content of the produced water is high, the solenoid valve diverts the freshwater to the shell side of the freshwater generator and emits an alarm signal.

The solenoid controlled dump valve diverts the flow back to the shell in case of fresh water salinity exceeding a predetermined value (maximum usually 10 ppm).

This prevent contamination of the made water.Excess salinity caused by so many factors including leakage of seawater at condenser or priming of evaporator or malfunctioning of demister, or many other reasons.In FWG,What cannot be condensed at the condenser Is called ‘incondensable gasses’ such as air and these gases are continuously ejected out by air/brineejector.This way, the fresh water generator shell is kept at high vacuum, which is a must to boil water at low temperatures.Suggested Read:

Tube Type Fresh Water Generator

- Tube type FWG also, known as the submerged type, because the steam coils are submerged.

- Sometimes it is known as Boiling FWG.

- The working and principle of the freshwater type tube generator is the same as the plate type fwg.

- Only difference in instead of plates, condenser and evaporators are tubes.

- The submerged tube type fresh water generator uses heat from the main engine jacket cooling water to produce water drinkable,by evaporating seawater due to high vacuum, which allows the feed water to evaporate at a comparatively low temperature.Steam can also be used as a source of heat instead of the main engine jacket cooling water.

- This type of freshwater generator is based on two sets of shell and tube heat exchangers, one act as an evaporator or heater and the another act as a condenser.

- The combined air / brine ejector creates vacuum condition in the evaporator chamber by driving sea water through the air / brine ejector and sea water supplied by the ejector pump to be delivered to the ejector for taking out the brine (concentrated seawater) and air.

- The temperature of the feed water in the evaporator chamber is about 50 degrees Celsius. The rate of supply of water to the evaporator is fixed by an orifice fitted at the feed inlet.

- Due to the vacuum condition inside the evaporator, the feed water evaporates at this temperature.The water spray and the droplets are partly removed from the vapor by the deflector mounted on the top of the evaporator and partly by the demister.

- The water droplets, which are separated, fall back into the brine, which is extracted by the water ejector.

- The desalted vapor, which passes through the demister, will come into contact with the condenser, where it will be condensed by incoming cold sea water.

- The distilled water is then removed by an integral freshwater pump (distillate pump) and controlled by a salinometer and a solenoid valve.

- If the salt content of the water generated is high, the solenoid valve transfers the freshwater to the freshwater generator shell side and gives an alarm signal.

- To get a better suction head, the distillate pump is placed in the freshwater generator plant at the lowest possible location.This is because the shell of the freshwater generator is at a lower pressure.

With the height of liquid column in the suction line, the distillate pump gets maximum net positive suction head.

Thermometers are installed to control the seawater to the condenser and the cooling cooling water to the evaporator .These thermometers did the work of controlling of both heating and cooling of these units.

The salinometer or salinity indicator is connected to the remote alarm, so that at the ship’s engine control room, very high salinity is immediately registered.